Customer Success Stories

Jaxon Energy Uses WinCC OA for Process Control and Information Systems

Jaxon Energy's goal was to implement a control system for their new refining facility in Vicksburg, Mississippi. The solution had to meet their operational requirements: flexibility to process many different types of raw material, remote and mobile access to the facility from their corporate headquarters, and historical data collection with powerful data analysis tools, all while being fully integrated with their corporate business systems.

They have worked with many SCADA solutions in the past but were limited by constant maintenance, lack of system stability, scalability, and little to no remote access capabilities of existing SCADA and DCS systems. They turned to their integration partner Corso Systems for recommendations and process engineering. With recent project success, certified WinCC OA solution partner, Corso Systems is no stranger to advanced technologies.

About the Project

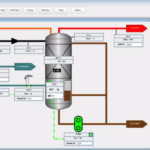

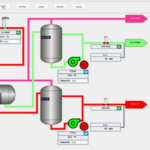

Jaxon Energy and Cam 2 International teamed up with Corso Systems to implement a process control and information system for its Vicksburg, Mississippi refinery. Jaxon leveraged the SIMATIC WinCC Open Architecture (WinCC OA) SCADA system for plant operation and secure remote and mobile access to their facility.

The foundation of the plant's control system is a SIMATIC S7-1200 PLC utilizing completely templatized equipment logic. WinCC OA, with templatized graphics and scripting objects, works seamlessly with the S7-1200 to operate the plant. This architecture reduced overall development time compared to similar systems by over 40%. The WinCC OA Ultralight client was deployed to enable remote access from Jaxon's Reno NV headquarters. WinCC OA's built-in historian tools historize process data and the built-in trending tools display a comprehensive and contextualized picture of process conditions. For shipping and receiving product reconciliation, Corso Systems developed a custom solution utilizing Microsoft's ASP.NET MVC platform. This system was designed to allow operators to track incoming raw material and outgoing finished product shipments, including quality information.

Combined with the control system, this provides an end-to-end account of the location and quality of every drop of material in the facility at any given time. “As a data-driven company, the goal of these systems is to transform the way our customers do business, enabling full shop floor to top floor information exchanges and companywide visibility into all aspects of an operation,” says Corso Systems President, Alex Marcy. He continues, “We consistently research and vet technologies on behalf of our customers. We were extremely pleased to discover SIMATIC WinCC Open Architecture as a solution to meet the growing needs of our industrial customers. WinCC OA makes system integration easier than any other SCADA system we’ve used in the past. We don't need to worry about where you can connect to, or how much effort it will take to meet our customer's needs. With WinCC OA we can do anything we need to, and enjoy the process because it is so quick and easy to get things done. Because of the system’s capabilities, we were pleased to recommend and implement WinCC OA at Jaxon Energy’s newest facility." Marcy says.

“As a data-driven company, the goal of these systems is to transform the way our customers do business, enabling full shop floor to top floor information exchanges and companywide visibility into all aspects of an operation.”

- Alex Marcy, Corso Systems

Further modernization efforts were realized by seamlessly integrating WinCC OA data into existing business operations systems, including shipping and receiving and accounting systems. Jaxon Energy’s General Operations Manager, Ron Bell, claims, “We’ve experienced the fastest startup and plant commissioning of all of our facilities and saved upwards of 40% compared to our previous best.“ He adds, “WinCC OA was the first product to not require any compromises on the way we want to run our facilities.”

WinCC OA's powerful object-oriented design enabled Jaxon Energy to replicate the functionality they were used to from DCS and other PLC based systems, including HMI configuration of valves, alarms, and interlock monitoring and management. Corso Systems was able to save upwards of 60% engineering time required to implement similar systems at other facilities.

Jaxon Energy’s Co-owner, Randy Soule adds, “Not only did the system as a whole cost less to develop and implement than anything we have used before, but it also saved us a huge amount of time. We were able to get up and running in less time than it has taken us to get everything configured with other platforms.” He continues, “We are now able to run our facility just how we like.”

In summary, SIMATIC WinCC Open Architecture increased Jaxon Energy’s operational visibility, reduced cost and connected systems for highly efficient operations.

WinCC OA Systems Integration by Corso Systems

Key Benefits

- Plant can be safely operated by both experienced operators and those new to Oil & Gas

- Robust controls using Siemens PLCs and WinCC OA software

- Total process visibility with trending, analytics, and reporting

- Remote access to system supports operational requirements, enabling, management of multiple facilities

- Startup duration and maintenance requirements minimized with up-front engineering and development time

Check out more success stories

Ready to find out more?

Drop us a line today to learn more about our digital platforms!