Customer Success Stories

WinCC OA Control System for Megawatt Energy Storage

As the smart grid quickly evolves into a distribution infrastructure for AC electricity with ever more sensory, interactive and transactional capabilities, a 150-year-old DC technology has emerged on the scene. It’s the wet-cell battery, but now with extremely advanced chemistry and designed, engineered and built to deliver multi-megawatt capacities and with plenty of smarts inside.

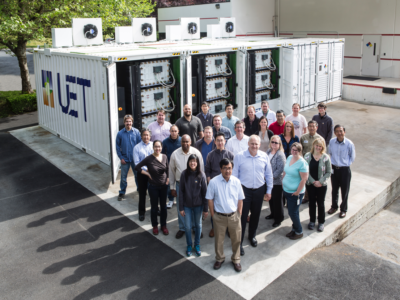

One of the world’s top suppliers of such energy-storage solutions is a small but growing company founded in 2012 called UniEnergy Technologies (UET). From its headquarters and manufacturing facility near Seattle, it makes and sells the Uni.System. This is a highly scalable, next-generation energy-storage solution for utility, commercial and industrial, microgrid and other applications housed in standard 20-foot shipping containers.

Inside the containers are tanks circulating an aqueous vanadium electrolyte, plus electrode stacks, sophisticated controls, and electronics. Big and massive as they are – one container full of electrolyte weighs 40 tons – their modular architecture enables UET’s customers to add as much capacity as they need with plug-and-play simplicity similar to adding data storage to today’s computer systems.

Unlike other battery types, such as lead-acid, lithium-ion and the newer zinc-air, UET’s system has no capacity fade and can be fully discharged without losing capacity any number of times over its 20-year lifecycle design. It also has no flammable components and no risk of thermal runaway, which can ignite surroundings and cause explosions in some environments.

As a buffer between bulk energy generation and sustained energy use, the Uni.System can provide near-instant energy for different durations. For short periods, just seconds long, its batteries can absorb and inject power into a grid or circuit to help regulate AC voltages and frequencies.

It also can supply power for medium durations from minutes up to an hour, which are typical of solar farms when clouds pass over and drop output to zero almost immediately. Finally, it can help utilities shift bulk energy for periods of two to four hours or longer. This enables them to store energy during an afternoon’s generation peak when grid loads are low, then discharge it during the early evening as loads peak.

Challenge

Develop a complete, highly scalable control system for multi-megawatt energy storage, ensure fastest time-to-market, and minimize recurring engineering costs.

According to UET’s Director of Electrical Engineering David Ridley, the company faced numerous challenges in bringing the Uni.System to life. Overall was the need to commercialize the vanadium electrolyte chemistry the company licensed from the U.S. Department of Energy’s Pacific Northwest Laboratory.

This involved designing and engineering the electrolyte tanks and pump systems, electrode stacks, instrumentation, and controls, all to fit compactly in a 20-foot container. “We needed to create a control architecture that’s scalable and extensible just like our product,” Ridley explains. “That way, if customers want to add another megawatt of capacity, no problem. Our controls needed to scale easily so that once we deliver another container and hook it up we could just increment our software to two megawatts and the customer is up and running.”

Simplicity and reliability were important too, for both customers and UET. “The last thing our customers want is to add complexity and risk to their operations, so we had to keep everything as simple as possible to ensure availability and serviceability,” he says, noting that service contracts enhance UET’s business model. “Of course, for our service business to be profitable, we need to minimize service calls by maximizing uptime and, if problems do occur, be able to troubleshoot and fix them remotely as much as we can.”

Among the Uni.System’s other design goals were low manufacturing costs and physical modularity. Ridley says that’s why the company chose the 20-foot shipping containers. “They’re available as pre-built commodities, saving materials sourcing and fabrication costs,” Ridley says. “They’re also stackable and easy to transport via multimodal logistics, whether by truck, rail or ship.”

Solution

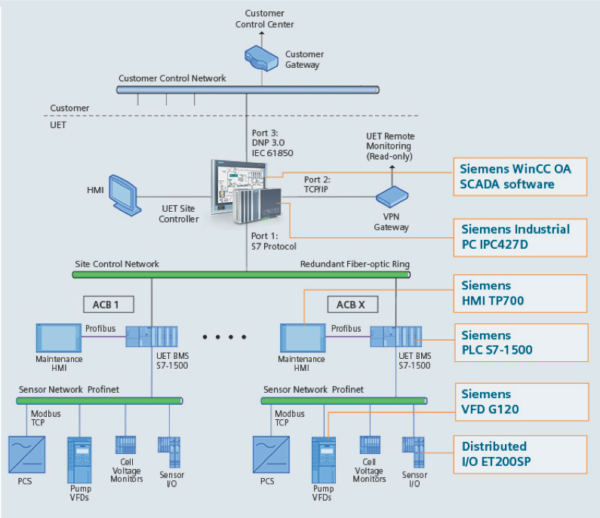

Utilize WinCC Open Architecture software by Siemens Industry to integrate key components from the Siemens Totally Integrated Automation (TIA) portfolio and other 3rd party vendor devices.

"What really stood out about WinCC OA is the truly extensible architecture, even during run-time. It shows just how powerful and flexible a software package can be when object-oriented design principals are utilized throughout the complete software package."

- David Ridley, Director of Electrical Engineering

Ridley and his team considered other major supervisory software suppliers in addition to their evaluation of WinCC Open Architecture. But they chose WinCC OA for several reasons – one being its complete object-oriented implementation and methodology.

“What really stood out about WinCC OA is the truly extensible architecture, even during run-time in most cases,” he says. “It shows just how powerful and flexible a software solution can be when object-oriented design principals are utilized throughout the complete software package.”

“With the Siemens WinCC OA software platform, we can forget all the protocols, drivers, and memory management issues that we’d have to code, then compile, test debug, recompile and on and on. This lets us keep a small, efficient team that just focuses on battery logic. That’s our value- add, not all that other effort.”

Another big attraction was the massively scalable and distributed nature of the WinCC OA platform, as evidenced by a number of the flagship deployments. “UET plans to become a major international supplier for the quickly growing utility energy storage market, with immediate plans to scale up production to over 100MW/year. Our demonstration projects are starting out at 0.5-2MW range, but typical renewal integration projects will range from 5- 20MW and peaker replacement projects will surpass 50MW. We needed a platform that will scale accordingly.”

Specifically, Ridley and his team developed the Uni.System site controller software using WinCC OA to perform the following key functions:

- Control and data aggregation: “A core component of our go-to-market strategy was to create a turn-key system which minimized project-specific integration work. Providing a single point interface allows us to abstract away the modular components and present a seemingly monolithic resource to the customer.”

- Interface and communication: “The site controller is the nerve center of the system which collects all the feedback and directs activities. The variety of interfaces and protocols provided by WinCC OA allows us to be flexible to customer requirements and component selection. “We utilize OPC DA/US, S7, Modbus TCP, IEC 61850, DNP 3.0, and others.”

- Battery system management: “Large scale battery energy storage systems are built using many repeating strings which all have slightly varying performance characteristics. The site controller actively manages these strings in order to maintain a consistent and balanced state of charge across the entire site.”

- Application control: “We decided to use a custom manager for our application development in order to utilize an automated software testing approach. The customer manager allows us to write code in C++ and validate using open source software testing frameworks.”

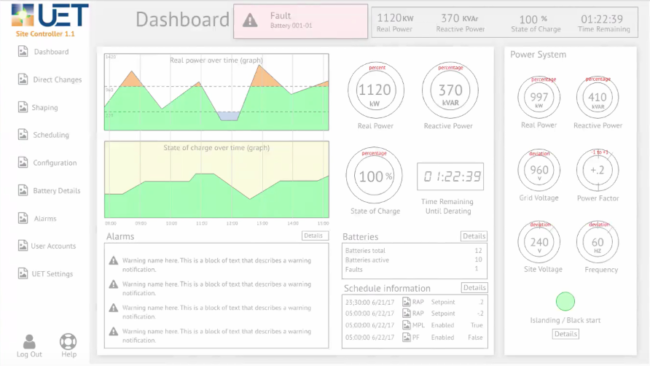

- Graphical user-interface: “A simple, visually appealing, and intuitive user interface is critical to the success of any product. We elected to use the Ultralight client because it will run on any web browser on any OS without requiring any software to be installed on the machine.”

- Data acquisition and telemetry: “Because the site controller already aggregates all sources of data, it provides a natural place for the data historian interface. We collect and archive all data points using an industry-standard OPC interface to our centralized data historian.”

Results

Time-to-market cut by 50 percent; site-specific programming efforts eliminated.

Ridley estimates that choosing WinCC Open Architecture helped UET cut its time-to-market in half, saving months of development time and conserving precious cash. But the real value that OA provides shows not in the first project, but in the avoided recurring engineering efforts required for subsequent projects.

“We now have a control system that can be run-time configured for any number of MWs and MWhs. No need to manually create tags, design new screens, add new interfaces or include more alarms. All of these tasks happen automatically as we programmatically instantiate additional battery objects.”

The second reason that WinCC OA will reduce future engineering costs is the flexibility of the platform. The open concept of SIMATIC WinCC Open Architecture allows the integration of a wide variety of components. From the automation level right up to operation and management level, the system allows finely tuned solutions. SIMATIC WinCC Open Architecture is platform-independent and available for Windows or Linux.

“The openness of the WinCC OA platform gives me the confidence that we’ll be able to incorporate any new interfaces, features, or standards that are required by our customers. Open Architecture provides a future-proof solution that won’t lead us down a technical dead end.”

Ridley also found that sole-sourcing with Siemens has greatly simplified procurement and support. UET saves time in ordering components and parts, not to mention the time when problems arise. “I don’t have to argue with supplier A and supplier B, pointing their fingers at each other,” he says. “With Siemens, it’s much more collaborative when we have a problem. We just work together to figure it out.”

Another benefit of working with Siemen has been the added credibility and trust UET gains among potential customers, especially those in the utility industry. “We certainly mention we’re using Siemens standardized components that have hundreds of thousands of hours of mean-time-to-failure,” he says. “Siemens is a trusted name across just about every industry and the utility industry, in particular. It sure helps build our credibility and move our sales cycles forward.”

Check out more customer success stories

Ready to find out more?

Drop us a line today to learn more about our digital platforms!