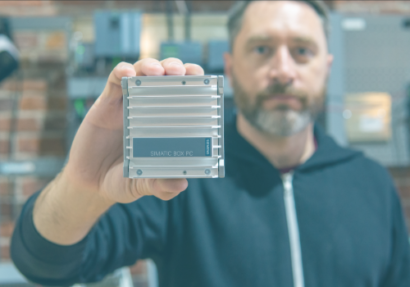

James and I had the chance to check out the new SIMATIC 127E Box PC this week, and we are happy to report that it packs a punch! The SIMATIC 127E is tiny and provides endless application possibilities. In this …

WinCC OA: SIMATIC 127E and WinCC OA Read More »

Read MoreCoined as an IoT edge gateway, the new SIMATIC IPC 127E delivers quite the punch considering how small it is. Just how small is it? Ask these guys! With up to 4GB RAM, 128GB solid-state drive and Intel Atom chipset …

News & Updates: SIMATIC IPC 127E by Siemens Read More »

Read MoreNepho what?! “Nepho” is Greek for cloud. So, I will ask in layman’s terms, are you afraid of the cloud or do you love the cloud? We use the cloud every day, but what about SCADA in the cloud? There …

Company Culture: Are you a Digital Nephophobe or Nephophile? Read More »

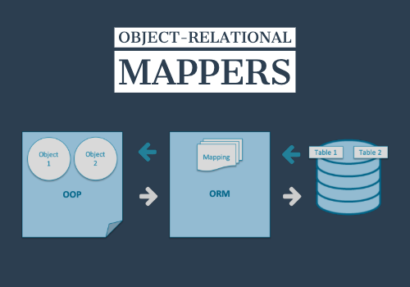

Read MoreWhat are Object-Relational Mappers (ORM)? To put it simply, it’s a tool that allows you to use your preferred object-oriented programming language and replace the need to write database queries. What’s the big deal? First and foremost, this makes application …

WinCC OA: Applying Object-Relational Mappers Read More »

Read MoreThis FAQ post was written for WinCC OA version 3.16. Which type of controller and simulation can I work with? S7-1200, S7-1500 S7-1500 Software Controller PLCSIM PLCSIM Advanced Is there a performance difference compared to the old S7 driver? The …

WinCC OA: S7 Plus Driver FAQ Read More »

Read MoreAs someone with an insatiable thirst for knowledge, I decided to take an eLearning course from Udemy. It was the perfect way to pass time during my exhilarating commute to Seattle. While listening to a lecture about company values and …

Company Culture: Creative Dissatisfaction Read More »

Read More- « Previous

- 1

- 2

- 3

- 4

Subscribe to KAASM News!

Stay up on information, News, and other great content by subscribing to our newsletter.